Tips and Tricks for Laser Processing of Wood

-

What to do if the wood warps during laser cutting?

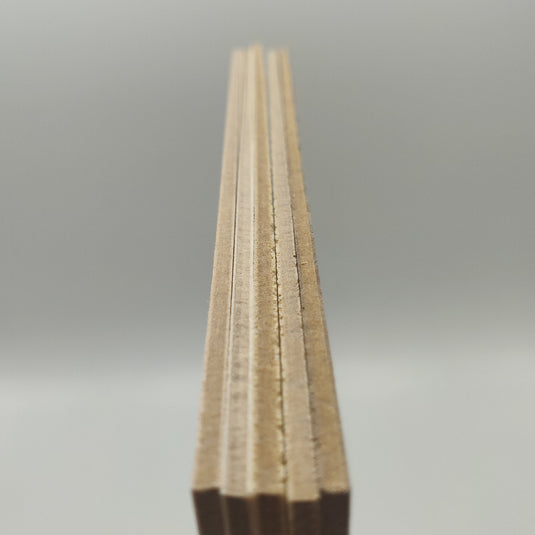

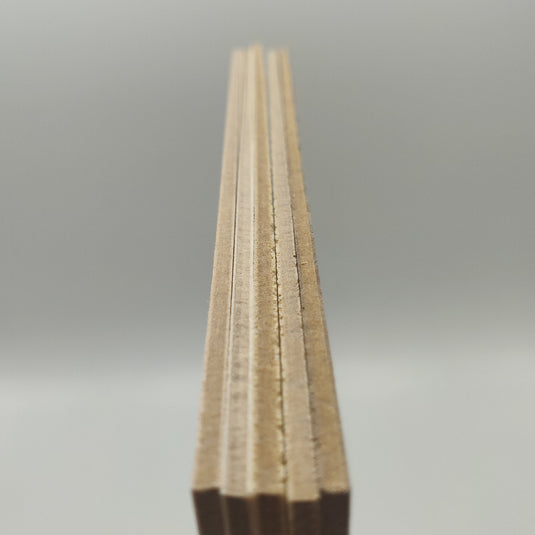

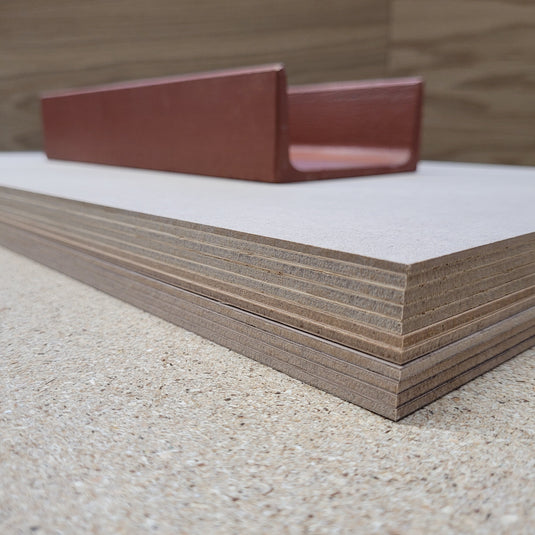

When laser cutting, especially thin wooden boards often warp, leading to inaccurate cuts and damaged projects. The cause is usually fluctuations in moisture and temperature that cause the wood to deform. To prevent warping, wood should be stored properly upon receipt: flat, dry, and on a level surface with spacers for air circulation. A constant humidity of 40–60% is ideal, and the wood should acclimate for several days before processing. Warped boards can be straightened again by weighting them down. When laser cutting, it helps to additionally fix the wood with magnets or clamps to prevent warping caused by the laser heat. Furthermore, a slower cutting speed and dividing the cut into several thin passes reduce heat exposure. This ensures a precise, clean cut without warping.

-

The most common mistakes when laser engraving wood – and how to avoid them

Those who start laser engraving wood often face unexpected problems: sooty edges, messy engravings, or warped workpieces are not uncommon. Many of these errors can be easily avoided. In our practical article, we show you what really matters – from the correct focus setting to choosing the right wood and optimal ventilation. Whether you are a beginner or advanced user: with these tips, your next laser project will definitely be cleaner and more professional.

-

Zero waste with wood scraps – What to do with offcuts & small pieces?

Wood scraps generated during production, in workshops, or schools are often considered waste but offer numerous possibilities for sustainable reuse. Small pieces of wood are well suited for making keychains, magnets, or wooden jewelry, which can be individually designed and used as gifts or items for sale. Additionally, schools and MakerSpaces appreciate wood scraps to use them for creative projects and educational purposes. Joining different wood scraps into patchwork wood panels also creates unique materials for further creative work. In this way, wood scraps actively contribute to resource conservation, sustainability, and community promotion through creative use.

-

Laser-cut wooden jewelry – Tips for lightweight and elegant pieces

Precious Plywood is an ideal material for handcrafted jewelry – whether earrings, necklaces, bracelets, or foot jewelry. It is stable, yet pleasantly lightweight and can be precisely processed with a laser. Due to its fine texture, it is especially suitable for delicate designs with high wearing comfort.

The size and shape of the jewelry pieces are a matter of taste – what matters is that they appear harmonious and are comfortable to wear. Rounded edges and good weight distribution further increase comfort. A finish with natural oils or waxes protects the wood, highlights the grain, and makes the jewelry durable.

-

"What makes good laser wood?" – What you should pay attention to when choosing wood for the laser

Not all wood is the same – especially when laser cutting, the choice of material makes the difference. In this article, you will learn what really matters for good laser wood: from uniform structure to high-quality gluing to pollutant-free processing. For clean cuts, precise engravings, and thoroughly successful projects.

-

Which wood for which purpose?

Whether delicate engraving or precise cutting – choosing the right wood is crucial for a successful laser project. In this guide, you will learn which types of wood are particularly suitable for which applications. From poplar to beech to noble veneers: discover the differences and find the ideal material for your next creative endeavor!

-

Laser engraving photos in wood – immortalize unique memories in natural material

When laser engraving photos on wood, a laser permanently and intricately burns the image into the surface. For this, the photo is first converted into a high-contrast black and white image and processed using a special dithering technique.

Light, finely grained woods such as Sycamore, Birch, or Beech are best suited. After engraving, residues can be removed and the wood can be refined with oil or varnish.

The result is personal, durable unique pieces – ideal as gifts or keepsakes.

-

Craft veneer: The perfect material for creative DIY projects

Craft veneer is a thin, flexible wood material that is ideal for a variety of craft and decoration projects. It consists of real wood layers and is available in different... -

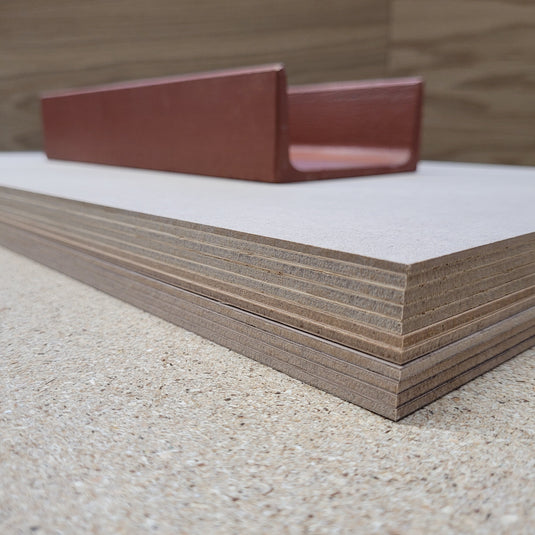

Thin wood panels: Properties, applications, and advantages in laser processing

Thin Wood Panels: Properties, Applications, and Advantages in Laser Processing Thin wood panels are an indispensable material in many craft and industrial fields. Whether for model making, furniture pieces, or... -

Craft wood panels for creative projects

Craft Wood Panels for Creative Projects: Why Birch Plywood and Poplar Plywood Are Ideal Craft projects require the right materials to achieve both creative and durable results. A particularly... -

Tips for Proper Storage of Plywood and Wood-Based Panels

Optimal storage of plywood and wood-based panels: A comprehensive guide Proper storage of plywood and wood-based panels immediately after delivery is a critical step to ensure their quality and functionality... -

Mecpow Laser: Excellent wood selection for your diode laser projects

Wood Selection for Projects with Wood for Mecpow Laser Diode lasers like the Mecpow Laser have reshaped the landscape of laser engraving and laser cutting by opening up impressive creative...