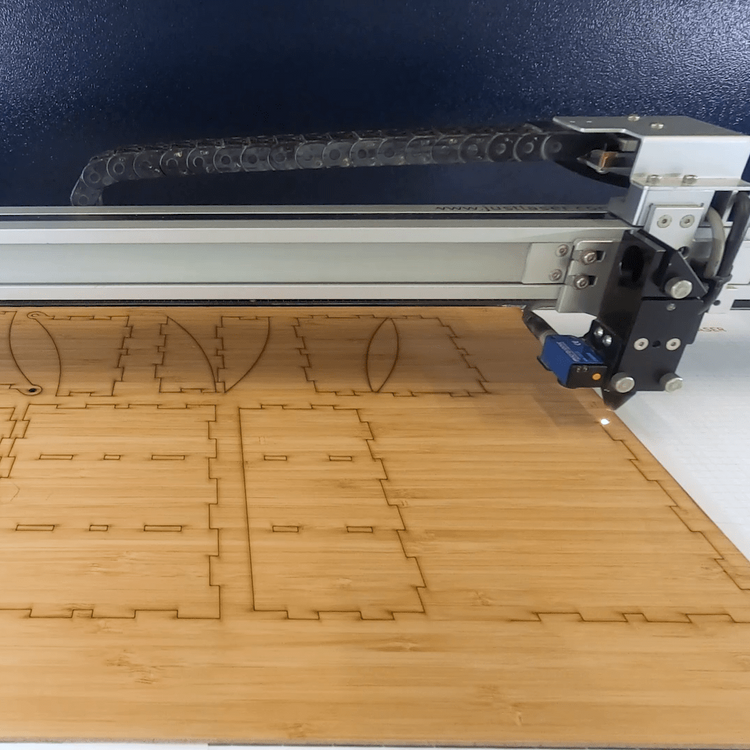

Laser cutting wood without burn marks: The best materials and techniques for clean results

Laser cutting wood is a popular technique for creative projects and industrial applications. However, this process often leaves unwanted burn marks that can affect the final product. In this blog article, you will learn how to successfully laser wood without leaving burn marks by using special wood products and supporting technologies such as air supply, airassist, and masking tape.

What to consider for laser cutting without burn marks

1. Choosing the right wood panels Choosing the right type of wood is crucial to minimize burn marks when laser cutting. Here are some of the best options:

- SmoothyPly: This material is known for its smooth, even surface, which is less prone to burn marks when laser cutting.

- Precious Plywood: The dense and solid nature of this wood helps reduce heat penetration, which decreases the formation of burn marks.

- Precious Uniply: Similar to plywood but with finer layers, this wood offers a uniform burning temperature that prevents burn marks.

- Solid wood strips: These provide a robust structure that is less prone to rapid burning, reducing the occurrence of burn marks.

- Fine veneers: Thin and exquisite, ideal for delicate engraving work without deep burn marks.

- Real wood stickers: These special stickers can be applied to any surface and laser cut without directly burning the underlying wood.

- Veneer paper and veneer on fleece: Both offer a controlled thickness that helps distribute laser energy evenly and minimize burn marks.

In addition to choosing the right wood, there are technical aids and methods that can prevent the formation of burn marks:

- Air supply systems: These improve air circulation around the laser area to quickly remove smoke and heat that can cause burn marks.

- Airassist: A directed airflow aimed directly at the laser cutting point that blows away smoke and cools the surface to reduce the risk of burn marks.

- Masking tape: This is applied to the wood to be laser cut and protects the surface from direct contact with smoke and ash generated during laser processing.

In summary:

Laser cutting wood without burn marks requires both the right choice of materials and the application of specific techniques. By using high-quality wood such as SmoothyPly, Precious Plywood, and other specially selected wood types combined with technical aids like air supply and airassist, you can ensure that your wood projects look clean and professional.

Let's get started: Are you ready to take your wood laser cutting technique to a new level and achieve flawless results without burn marks? Browse through our website WOOD4PROS.COM for more information and discover our range of specially selected wood products that will help you perfectly realize your projects.

Be the first to hear about news!

Promotions, new products, and special offers. Directly in your inbox.